The Ultimate Guide to 3D Laser Scanners (Updated for 2025)

Whether you’re surveying a building site, documenting a historic landmark, or creating virtual tours for real estate, 3D laser scanners are fast becoming essential tools across a wide range of industries. But with so many models, specs, and use cases to consider, knowing where to start isn’t always easy. This guide walks you through how 3D scanners work, where they’re used, what to look for when choosing one, and how the latest models stack up in 2025 — with honest insights, practical comparisons, and a focus on helping you find the right tool for the job.

Why 3D Laser Scanners Are Essential Tools in 2025

In 2025, 3D laser scanning will remain a game-changing technology in industries such as construction, land surveying, real estate, archaeology, and industrial inspection. Professionals increasingly rely on these devices to capture real-world environments with speed, accuracy, and detail.

By converting physical spaces into digital models, 3D laser scanners allow for better planning, analysis, and decision-making. Whether you're new to the technology or in the market for an upgrade, this guide walks you through the fundamentals of how 3D scanners work, what they’re used for, how to choose the right model, and which products will lead the field in 2025.

How 3D Laser Scanners Work

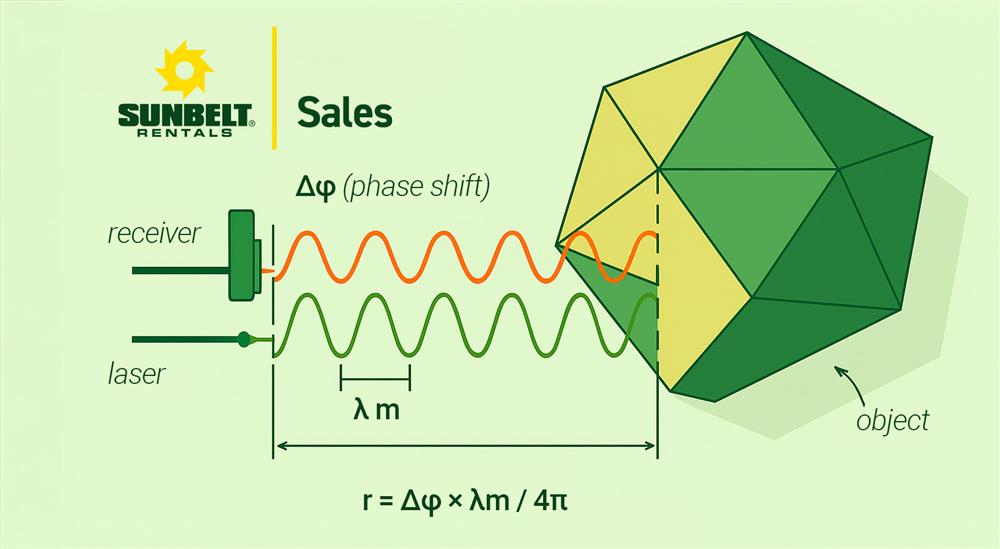

At their core, 3D laser scanners use laser beams to precisely measure the shapes, distances, and features of physical objects and environments. Here's how the process works, step by step:

1. Laser Projection - The scanner emits a laser beam onto the surface of a target—this may be a single point, a line, or a rapidly spinning laser that sweeps across the entire scene.

2. Reflection and Measurement - As the beam hits surfaces, it reflects back into the scanner. The scanner then calculates the distance between itself and each point using either Time-of-Flight (measuring how long the light takes to return) or phase shift (measuring the phase difference in the returning signal).

3. Data Capture - This process happens thousands—or even millions—of times per second, creating a highly detailed "point cloud." Each point has a precise location in 3D space and may include extra information like colour or reflectivity.

4. Data Processing - Specialist software is used to clean, align, and stitch multiple scans together. The result is a complete and accurate 3D model of the space or object.

5. Visualisation and Analysis - Once processed, the scan data can be used in a range of platforms—BIM, CAD, inspection tools, or visualisation software. It can support tasks from architectural planning to structural verification and even historical archiving.

To put it into a paragraph, a 3D laser scanner projects lasers onto surfaces, measures the reflected light to calculate distances and shapes, and then converts that data into a detailed three-dimensional model. Thanks to ongoing advancements in accuracy, speed, and usability, 3D scanning has become more accessible and effective than ever before.

Our Personally Top-Rated 3D Scanners Available at Sunbelt Sales (2025)

Here are some of the most trusted models we currently stock—each recommended for specific needs:

8 Things to Look For in a 3D Laser Scanner

Choosing the right scanner isn’t just about specs—it’s about how those specs fit your needs. Here's what to consider before investing:

1. Accuracy and Precision - Some tasks demand sub-millimetre precision (e.g., structural surveys, preservation projects), while others—like real estate walkthroughs—only require moderate accuracy. For high precision, scanners like the Leica RTC360 are top-tier choices.

2. Range - Long-range capability is essential if you’ll be scanning large outdoor areas. The FARO Focus Premium, for example, can accurately capture data up to 400 metres away.

3. Portability - Are you constantly moving between sites or scanning tight indoor areas? Lightweight models like the Leica BLK360 are ideal, although there may be trade-offs in range or resolution.

4. Ease of Use - If you're new to scanning—or if multiple team members will use the device—look for models with intuitive interfaces. The FARO Focus Premium is often praised for its user-friendliness.

5. Speed of Capture and Processing - Speed matters in fast-paced environments or deadline-driven projects. The Leica RTC360 performs full-dome scans in under three minutes, which can significantly improve workflow.

6. Software Compatibility - Your scanner should integrate smoothly with your existing software (CAD, BIM, virtual tour platforms, etc.). Seamless data transfer can save time and reduce errors.

7. Cost and Value - High-end scanners come with advanced features, but they may be unnecessary if you're not using those features. The Matterport Pro2 provides excellent value for real estate and interior design professionals.

8. Intended Use - It’s important to match the scanner to your application. The best scanner for engineering inspections won’t necessarily be the best for a virtual home tour.

How Much Do 3D Scanners Cost?

Like most specialist equipment, the price of a 3D laser scanner varies depending on its use. Whether you're scanning buildings, creating immersive walkthroughs, or working on engineering-grade inspections, a wide spectrum of tools are available, and it's important to align your investment with your application's demands.

High-End Models (£40,000+)

Scanners such as the Leica RTC360 or FARO Focus Premium sit firmly in the top tier. Built for industrial use, they offer exceptional accuracy, fast data capture, and seamless integration with professional-grade software. These are the tools of choice for large-scale construction projects, detailed structural surveys, and critical engineering tasks where precision can't be compromised.

Mid-Range Models (£10,000–£40,000)

Scanners like the Leica BLK360 strike a solid balance between performance and portability. They're ideal for architectural visualisation, building surveys, interior scanning, and heritage work. This tier is often the go-to for professionals who need reliable results across varied projects without stepping into full industrial budgets.

Entry-Level Options (~£2,700-£10,000)

Devices such as the Matterport Pro2 are perfect for real estate, interior design, and virtual tours. They’re intuitive, cost-effective, and quick to deploy, making them a smart choice for professionals whose work focuses more on spatial presentation than millimetre-level precision.

Why Accuracy Matters — and When to Be Cautious

It’s tempting to opt for a lower-cost scanner, especially when working to a budget or testing out the technology. But it’s worth considering what’s at stake. Inaccurate or incomplete data might not just affect your workflow — it could lead to costly rework, safety issues, or missed opportunities.

For example:

- In engineering inspections, small measurement errors can lead to faulty assemblies or overlooked wear and tear.

- In heritage preservation, a missed detail could affect restoration accuracy or lead to permanent data loss.

- In construction, inaccurate as-built data may result in costly design clashes or delays further down the line.

In short, not every project needs top-tier hardware, but for applications where precision and accountability matter, cutting corners on your scanner can cost more in the long run.

Try Before You Commit

Sunbelt Sales offers rental options for a wide range of 3D scanners if you're not ready for a full investment. It’s an ideal way to access professional-grade equipment on a short-term basis — whether trying a new workflow, covering a one-off project, or simply exploring the technology before purchasing.

Where 3D Laser Scanners Are Used — and How They Compare to Traditional Methods

3D laser scanning has become a standard tool across a wide range of industries, not only because of its detail and efficiency but also because it replaces older methods that were often slower, less accurate, and in some cases, more hazardous. Here’s a closer look at how 3D scanning is applied in 2025 and how it compares to traditional surveying and measurement techniques.

| Forestry and Environmental Management - In forestry, 3D scanning is used to measure tree heights, estimate biomass, and assess canopy density. Previously, this type of data collection involved physical access to tree canopies, often requiring professionals to climb trees or use elevated platforms. This posed obvious health and safety concerns and was highly labour-intensive. Modern scanners now allow for accurate, remote assessments, improving both safety and consistency while significantly reducing time in the field. |  |

| Heritage Preservation - Capturing historic buildings or artifacts once required manual measuring tools, hand-drawn plans, and physical interaction with delicate structures. These processes could be time-consuming and, in some cases, risk causing unintentional damage. 3D laser scanners now offer a non-contact alternative, allowing conservators to digitally capture and document sites in fine detail without disturbing the original structure—ideal for restoration, archiving, and virtual exhibition purposes. |

| Construction and Architecture - Traditional methods on construction sites often involved total stations, tape measures, and paper plans that quickly became outdated. Manual measurements also introduced the risk of human error. Today, 3D scanners can capture as-built conditions quickly and accurately, helping teams monitor progress, detect deviations, and produce reliable digital records. This improves both on-site decision-making and long-term documentation. |  |

| Industrial Inspection - In industrial settings, inspections used to rely on physical gauges, callipers, and other contact tools to verify component alignment or wear. These methods could be time-consuming and were limited in the detail they could capture. With 3D scanning, engineers can now assess high-resolution complex equipment geometries, identify deformation or wear early, and ensure critical components meet exact tolerances—all without dismantling machinery. |

Real Estate and Interior Design - Property professionals traditionally relied on photography, sketches, and hand-measured floorplans to market or plan spaces. These methods lacked spatial accuracy and required multiple site visits. With 3D scanning, a single scan can capture every room with exact dimensions and generate immersive walkthroughs for remote viewing, virtual staging, or interior planning. It’s faster, more efficient, and produces a more engaging experience for clients. |  |

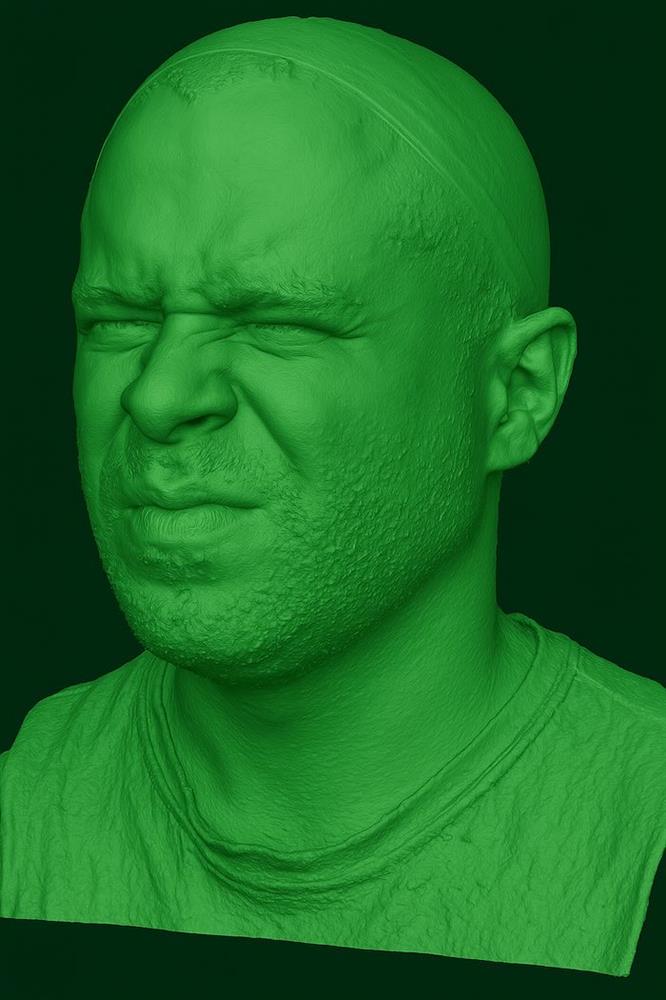

| Film, Gaming, and Digital Media - Creating 3D models for games or films once involved manual modelling based on photographs or rough measurements. This was a time-consuming, iterative process that depended heavily on the artist’s skill. Scanning has streamlined this workflow by allowing real-world objects, people, or environments to be captured in high resolution and directly imported into production pipelines, saving both time and budget while improving realism. |

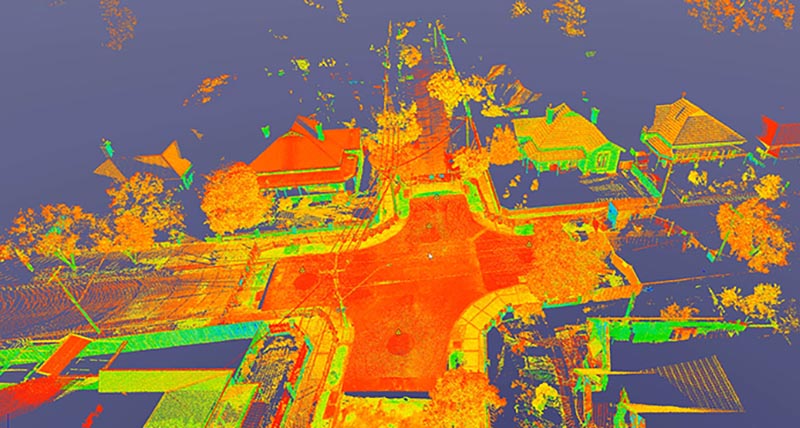

| Land and Topographical Surveying - Topographic surveys traditionally required surveyors to spend days or weeks traversing terrain with theodolites, GPS tools, and measuring tapes. Visibility issues, dense vegetation, and inaccessible areas often limited data collection. Today’s laser scanners—sometimes even drone-mounted—can collect millions of data points across large areas in a matter of hours, creating detailed digital terrain models with minimal ground disruption. |  |

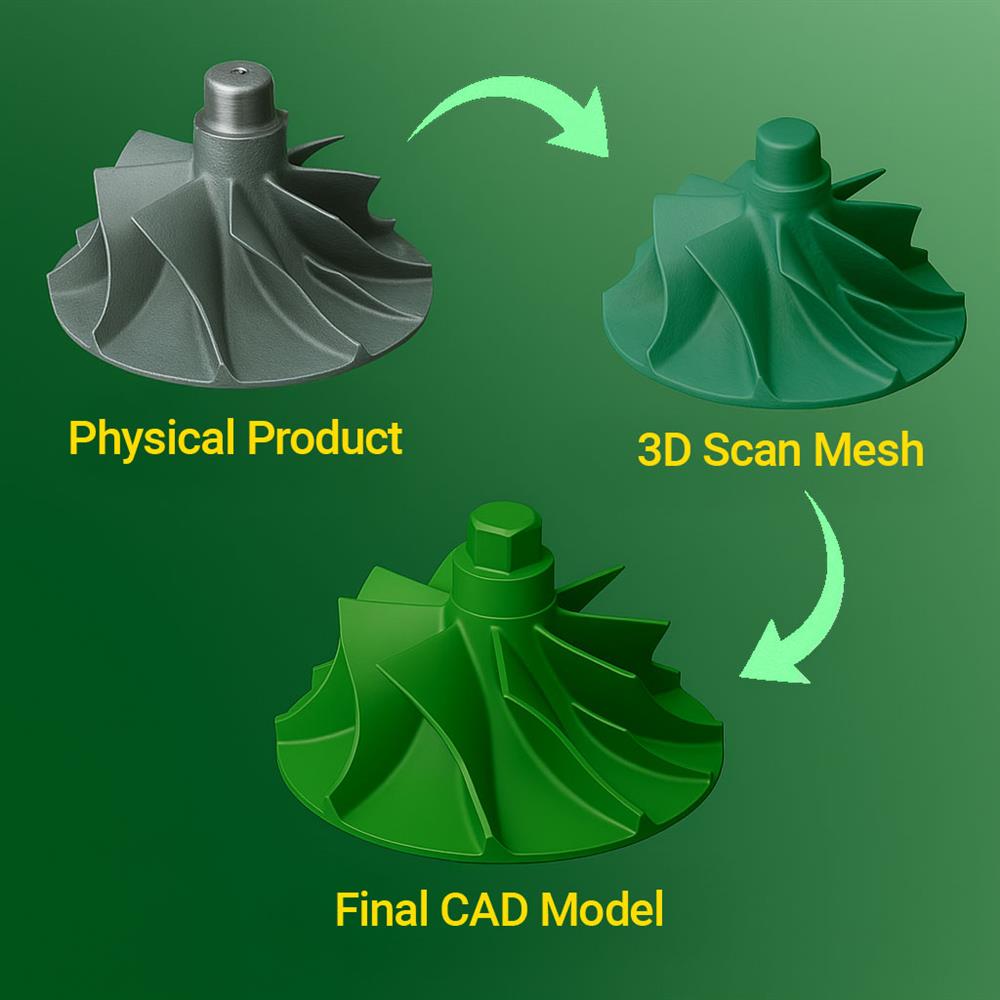

| Reverse Engineering - When original design documentation is missing, replicating parts used to involve detailed manual measurement and trial-and-error CAD modelling. This approach was slow and prone to inaccuracies. 3D scanning now enables full geometry capture of existing parts, producing precise digital models that can be used for reproduction, redesign, or quality comparison. |

Wrapping It All Up

Choosing the right 3D laser scanner is more than specs—it’s about aligning the tool with your needs, budget, and workflow. Whether managing a major construction site, restoring a historic landmark, or creating a virtual tour of a new property, the right scanner can make all the difference.

Explore the full range of 3D laser scanners available at Sunbelt Sales. And if you need guidance, our team is on hand to help you compare models, discuss rental options, and find the ideal scanning solution for your business.